Contact with

us for any

solution

Call Anytime

+91 9691176667

Mixer

At Premier Industrial Tools, we take pride in offering a specialized range of industrial mixers engineered to deliver superior performance, reliability, and efficiency. Our mixers are designed to handle the most demanding applications across a broad spectrum of industries, including chemicals, pharmaceuticals, food processing, construction, and more. With over 25 years of expertise and more than 250 successful projects, our mixers are a testament to our commitment to innovation and customer satisfaction.

Why Choose Our Mixers?

With Premier Industrial Tools, you’re not just getting a mixer; you’re investing in a solution that enhances productivity, reduces operational costs, and stands the test of time. Let us help you achieve your industrial goals with our unparalleled range of mixers.

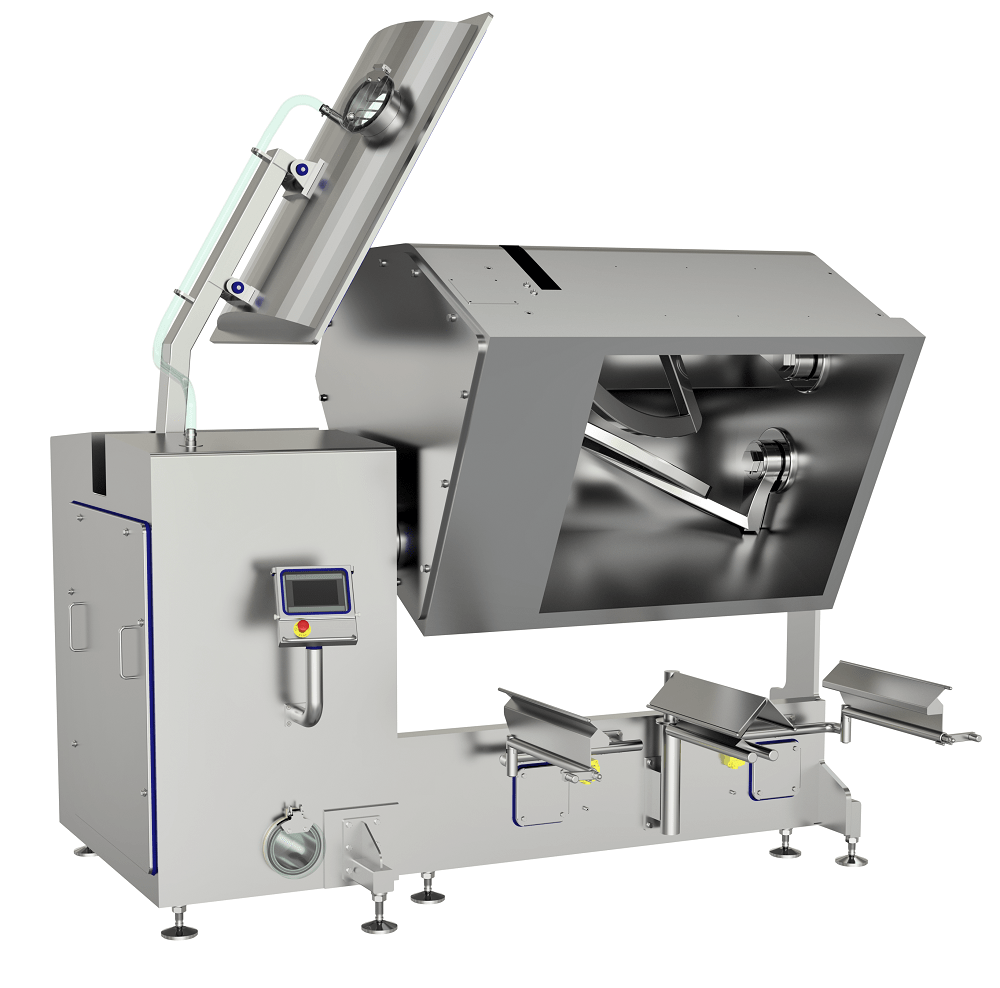

Sigma Mixer

Advantages of the Sigma Mixer

Features

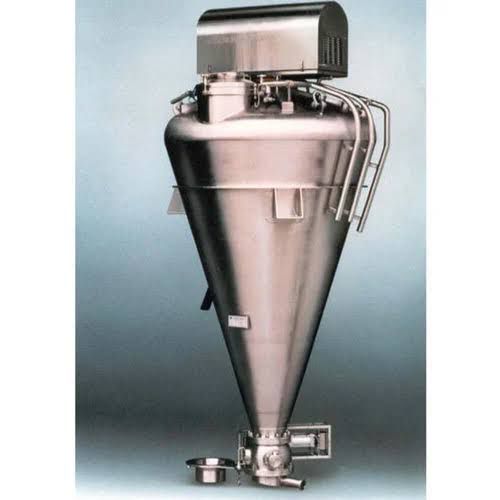

Nauta Mixer

Advantages of the Nauta Mixer

Features

Z arm Mixer

Advantages of the Z Arm Mixer

Features

Sigma Mixer Kneader

Advantages of the Kneader Mixer

Features

Screw Type Mixer

Salient Features

| Model | Working Capacity(Capacity – Litres) | Gross Capacity(Capacity – Litres) | General (Motor (H.P.)) | Heavy Duty (Motor (H.P.)) |

|---|---|---|---|---|

| ASM – 50 | 50 | 80 | 5 H.P. | 7.5 H.P. |

| ASM – 75 | 75 | 110 | 7.5 H.P. | 10 H.P. |

| ASM – 100 | 100 | 150 | 10 H.P. | 15 H.P. |

| ASM – 150 | 150 | 200 | 15 H.P. | 20 H.P. |

| ASM – 200 | 200 | 300 | 20 H.P. | 25 H.P. |

| ASM – 400 | 400 | 550 | 30 H.P. | 40 H.P. |

| ASM – 500 | 500 | 700 | 40 H.P. | 50 H.P. |

Features

What industries do your mixers cater to?

Our mixers are designed to serve a wide range of industries, including food processing, pharmaceuticals, chemicals, plastics, and more.

Can your mixers handle high-viscosity materials?

Yes, our Sigma and Kneader mixers are specifically designed to handle high-viscosity materials such as pastes, rubber, and adhesives.

Do you provide customized mixer solutions?

Absolutely! We offer customizable mixers to meet the specific requirements of your industrial applications.