Contact with

us for any

solution

Call Anytime

+91 9685187059

+91 9691176667

+91 9691176667

Soap/Detergent plant

A Soap/Detergent Plant is a facility designed for the production of soap and detergent products, including bar soap, liquid soap, laundry detergents, and dishwashing products. These plants involve various stages of processing, from the formulation of raw materials to the final packaging of finished goods. The production process involves the use of specialized equipment for mixing, blending, emulsifying, drying, and packaging, all designed to ensure quality, efficiency, and safety.

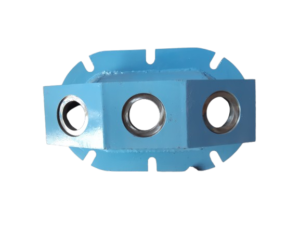

Key Equipment in Soap/Detergent Plant

Mixing and Blending Equipment: Used for blending raw materials such as oils, surfactants, and other additives.

Reactors: Used for saponification, where oils or fats are chemically processed to form soap.

Spray Dryers (for powder detergents): Equipment for drying detergent mixtures into powder form.

Soap Molding Machines: Used to shape soap into bars or blocks.

Filling and Packaging Machines: These machines automatically fill and seal soap or detergent products in bottles or packages.

Benefits of Soap/Detergent Plants

High Efficiency: With automation and advanced machinery, these plants can produce large volumes of soap and detergent products in less time.

Cost-Effective: The ability to optimize raw material usage and reduce waste makes the plant a cost-effective solution for manufacturers.

Versatility: Soap and detergent plants can produce a variety of products, from personal care items to heavy-duty industrial cleaners.

Quality Consistency: With precise control over production processes, these plants ensure high-quality products with consistent performance.

Features of a Soap/Detergent Plant

Automation: Most modern soap and detergent plants are highly automated, ensuring faster production and reducing human labor. Automated systems also help maintain consistent product quality.

Energy Efficiency: Energy-efficient equipment helps minimize power consumption while maintaining high production rates. This can include heat recovery systems and low-energy mixers.

Product Customization: Soap and detergent plants can produce various formulations with customizable fragrances, colors, and cleaning properties, depending on market demands.

Quality Control: These plants have dedicated quality control labs that test raw materials, in-process products, and finished goods to ensure they meet industry standards and consumer expectations.

Safety Standards: Given the use of chemicals and high-temperature processes, soap and detergent plants follow stringent safety protocols to protect workers and the environment.