Contact with

us for any

solution

Call Anytime

+91 9691176667

Conveyor

At Premier Industrial Tools, we understand that efficient material handling is critical to optimizing operational workflows across various industries. That’s why we provide a comprehensive range of Material Handling Conveyors, each meticulously designed to meet the unique demands of manufacturing, logistics, warehousing, food processing, and beyond.

Our conveyors combine robust construction with advanced engineering to ensure reliability, efficiency, and minimal downtime. Whether your requirements involve moving light goods or handling heavy industrial loads, we have the right conveyor solution to suit your needs.

Why Choose Our Conveyors?

With over 25 years of expertise and a proven track record of delivering over 250 successful projects, Premier Industrial Tools is a trusted name in material handling solutions. Our team of skilled professionals and state-of-the-art R&D facilities ensure that we deliver conveyors that exceed your expectations in performance and reliability.

Let us help you streamline your material handling operations with solutions tailored to your specific needs.

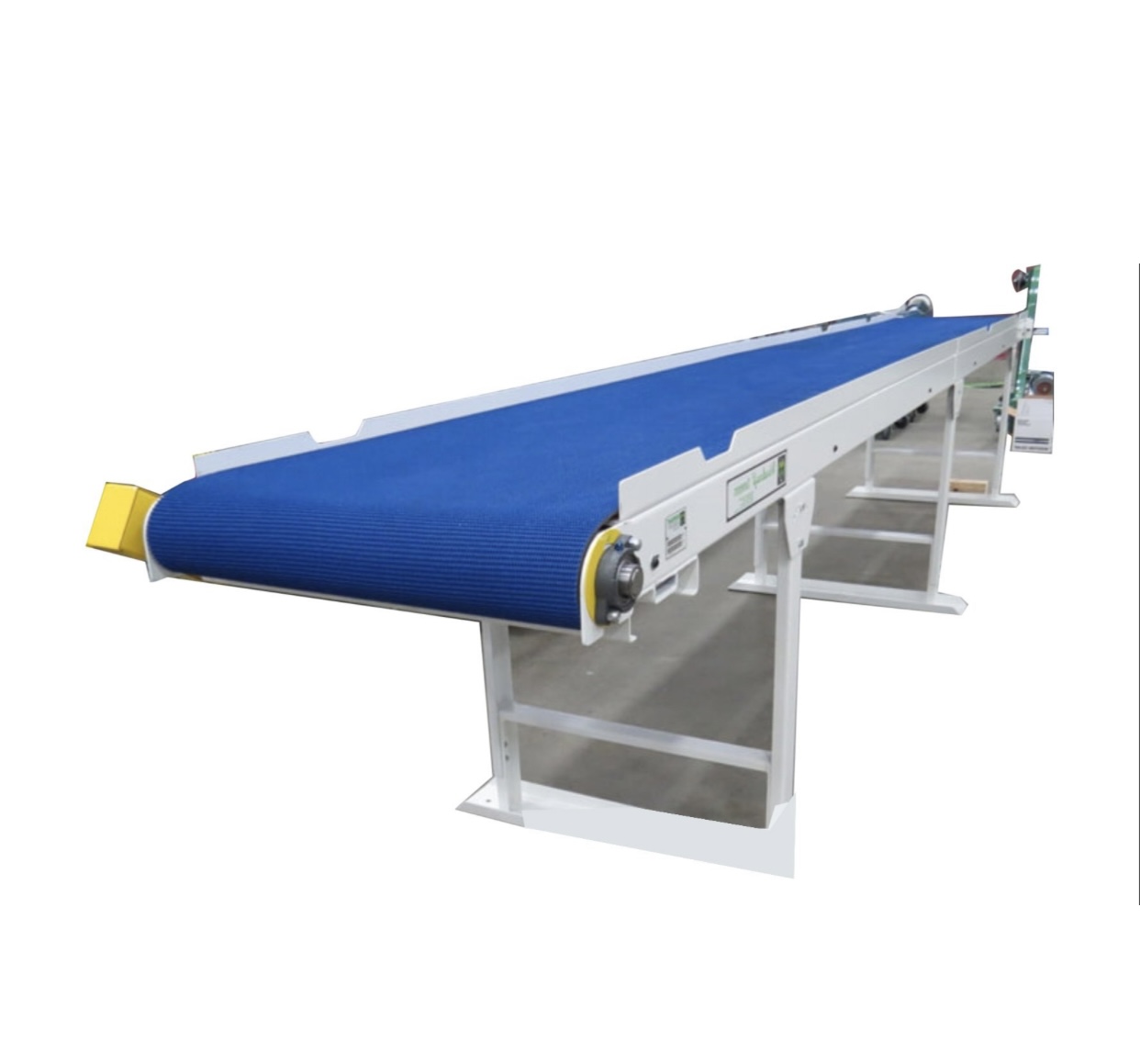

Belt Conveyor

Benefits at a Glance

With its durable design, customizable options, and proven reliability, the Belt Conveyor from Premier Industrial Tools is the backbone of efficient material handling systems across diverse industries.

Features and Applications

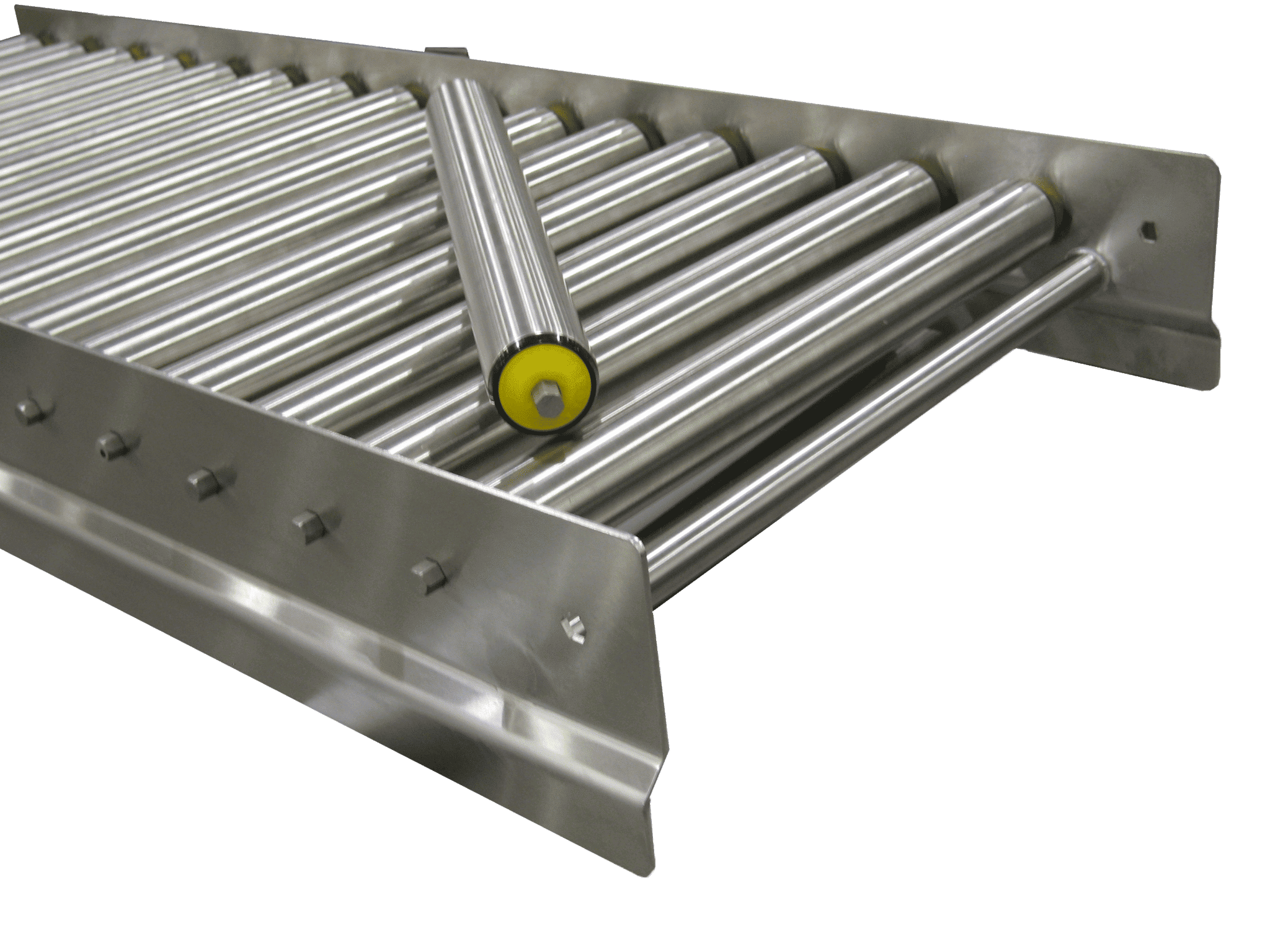

Roller Conveyor

Applications

Key Features

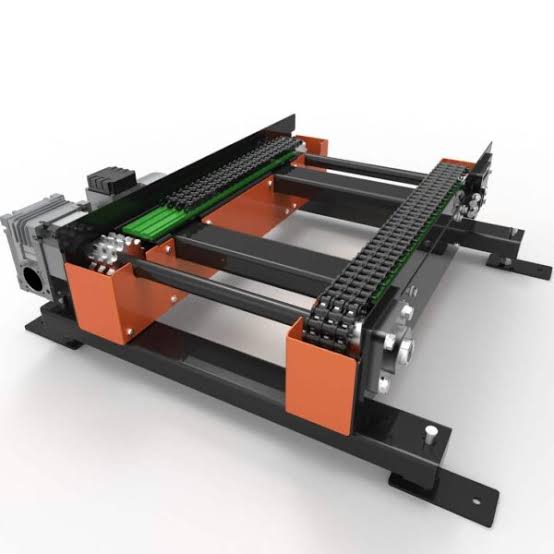

Motorized Roller Conveyor

Applications

Key Features

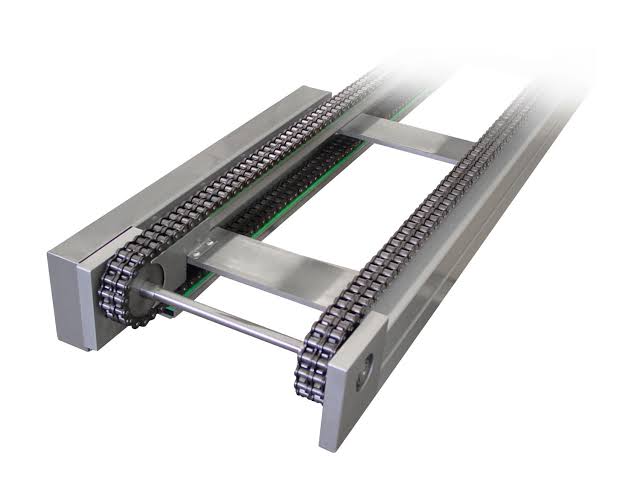

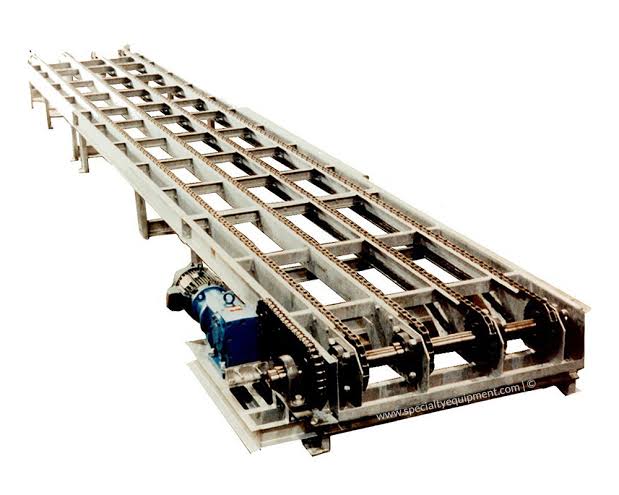

Chain Conveyor

Applications

Key Features

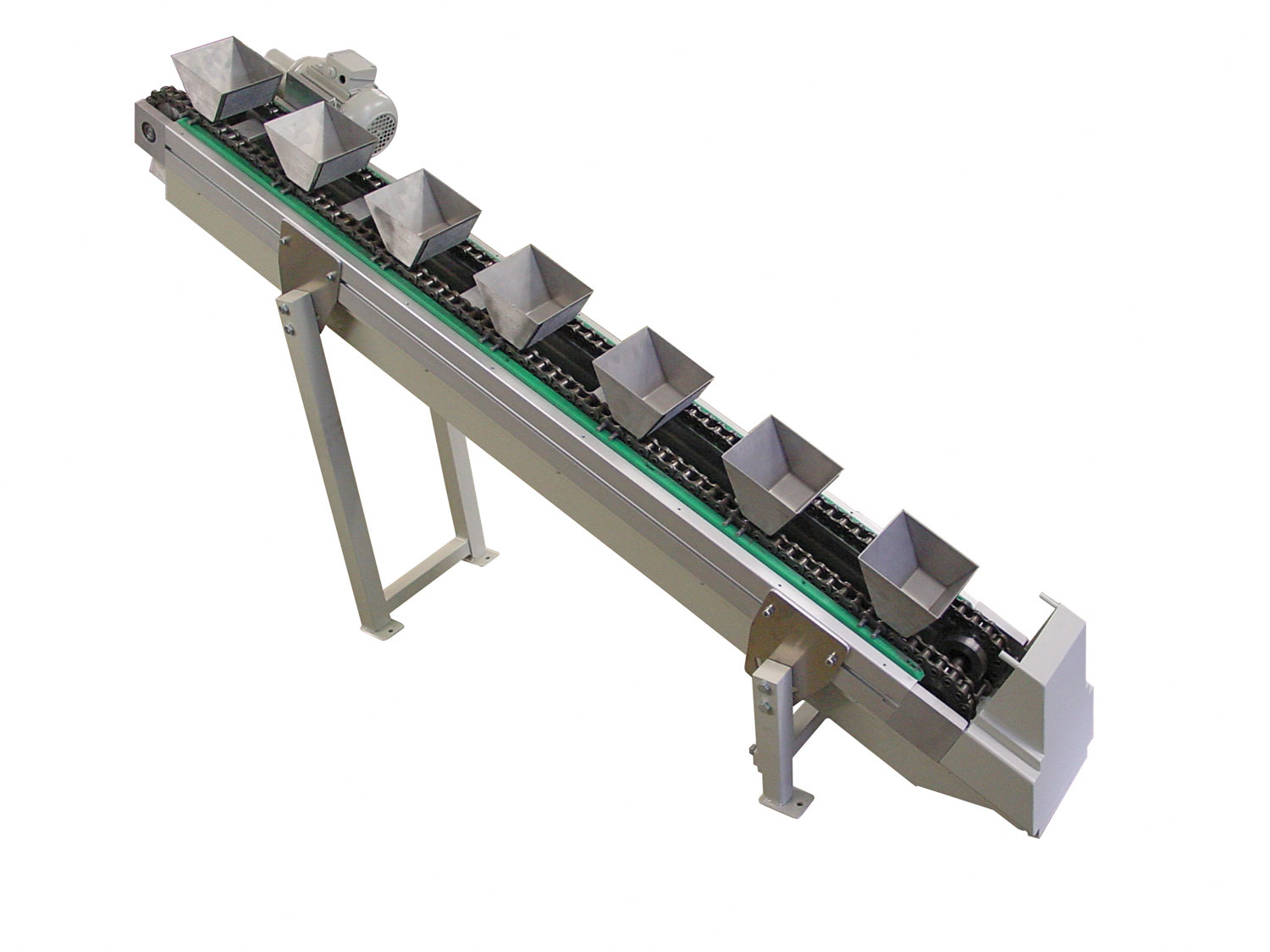

Bucket Conveyor

Applications

Key Features

What are the different types of conveyors available?

Conveyor systems come in various types, including belt conveyors, roller conveyors, motorized roller conveyors, chain conveyors, and bucket conveyors. Each type is designed to handle specific material types, load capacities, and operational needs.

Are conveyors energy-efficient?

Many modern conveyor systems are designed to be energy-efficient, especially motorized roller conveyors and those equipped with energy-efficient motors. They help reduce operational costs and improve overall system performance while minimizing energy consumption during transport processes.

How do I choose the right conveyor for my business?

- To choose the right conveyor, consider factors such as the type of materials you are handling, the weight of the loads, the required speed, available space, and whether your process requires a powered or gravity-fed conveyor system. Consulting with an expert can help determine the best option based on your operational needs.