Contact with

us for any

solution

Call Anytime

+91 9685187059

+91 9691176667

+91 9691176667

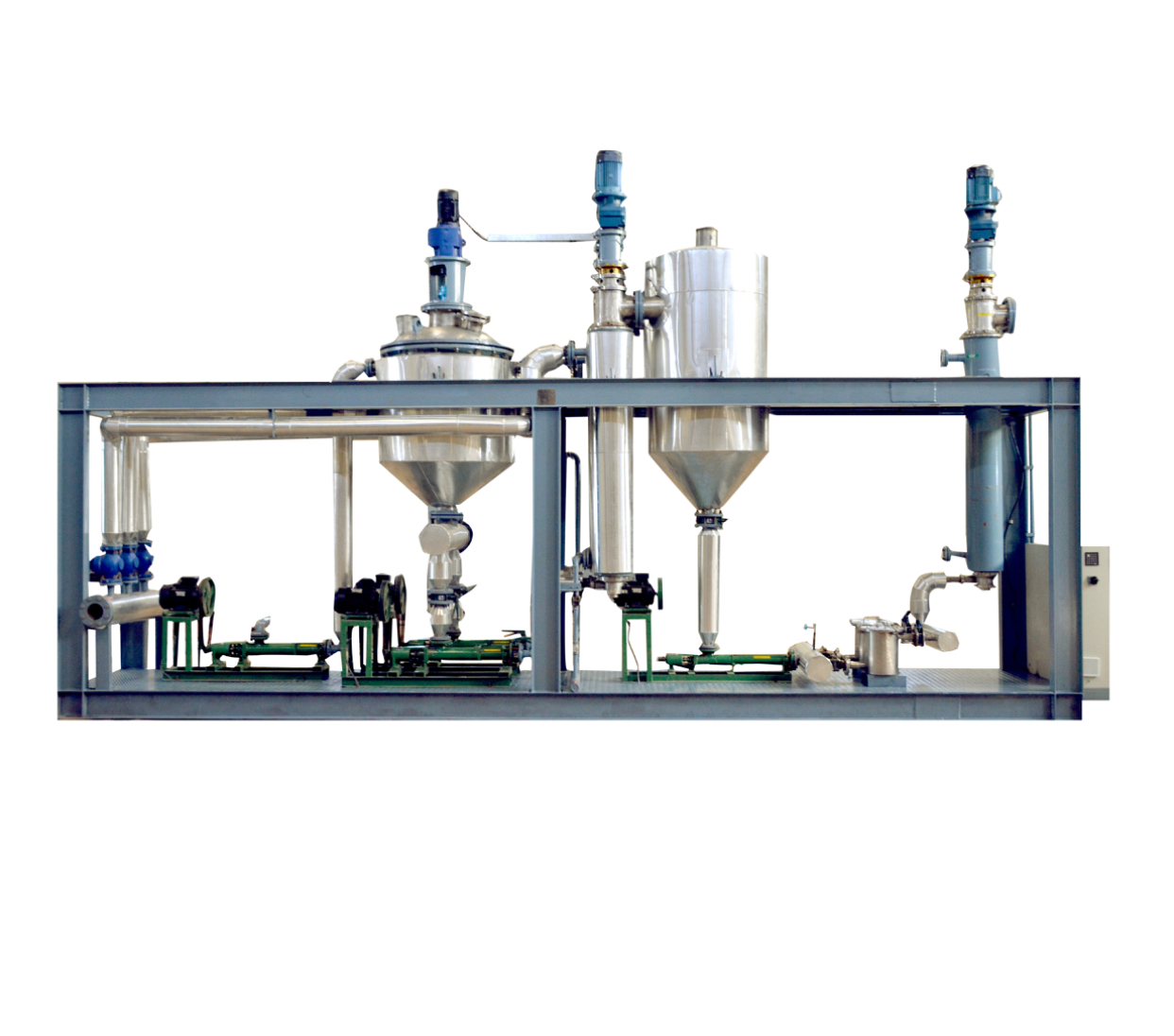

Lecithin Plant

A Lecithin Plant is a specialized facility designed for the extraction, processing, and production of lecithin, a type of phospholipid that plays a critical role in various industries. Lecithin is primarily derived from vegetable oils such as soybeans, sunflowers, and rapeseed. It is widely used in the food, pharmaceutical, cosmetic, and industrial sectors due to its emulsifying, stabilizing, and moisturizing properties. The lecithin extraction process involves several steps that transform raw vegetable oil into high-quality lecithin that can be used in various applications.

Types of Lecithin:

Soy Lecithin: The most widely used lecithin, obtained from soybeans. It is often used in food production, pharmaceuticals, and cosmetics due to its emulsifying and stabilizing properties.

Sunflower Lecithin: This lecithin is extracted from sunflower seeds and is preferred for non-GMO applications. It is commonly used in food products, dietary supplements, and cosmetics.

Rapeseed Lecithin: Extracted from rapeseed (canola), this lecithin is used for applications where specific characteristics of lecithin, such as flavor and color, need to be controlled.

Key Equipment in Lecithin Plant:

Oil Press Machines: Used for the mechanical extraction of oil from raw seeds.

Solvent Extraction Units: Employed when solvent extraction methods are used to obtain oil from the seeds.

Degumming Units: Involves adding water or weak acids to crude oil to separate lecithin and impurities.

Refining Units: For neutralization, bleaching, and decolorizing lecithin to improve its quality.

Drying Equipment: Used to remove moisture from lecithin after refining.

Powdering or Granulation Units: For turning lecithin into powdered or granulated forms suitable for different applications.

Packaging Equipment: For packaging lecithin into containers for distribution.

Key Features of a Lecithin Plant:

Automation and Control: Modern lecithin plants are automated for efficient production. Advanced monitoring systems help ensure consistent product quality, reducing waste and energy consumption.

Energy Efficiency: Lecithin plants are designed to optimize energy use, especially in heating and drying processes. Efficient energy management helps reduce overall operational costs.

Customization: Lecithin plants can be customized to produce lecithin in various forms (liquid, powder, granules) to meet the specific needs of industries like food, pharmaceuticals, and cosmetics.

Quality Assurance: Plants follow strict quality control standards to produce high-quality lecithin that meets the requirements of various sectors. Regular testing ensures purity, flavor, and other essential properties.

Benefits of Lecithin

Emulsifying Agent: Lecithin's primary role is to stabilize mixtures of oil and water, ensuring the consistency and quality of products.

Non-Toxic and Safe: Lecithin is considered safe for consumption and use in various products.

Natural Source: Lecithin is a natural product, making it an attractive alternative to synthetic emulsifiers and stabilizers in many industries.

Improved Product Shelf Life: Lecithin helps extend the shelf life of many products by preventing ingredients from separating.