Contact with

us for any

solution

Call Anytime

+91 9685187059

+91 9691176667

+91 9691176667

Material Handling Equipment

Material handling equipment plays a crucial role in the efficient transport, storage, and management of materials throughout various industries. At Premier Industrial Tools, we offer a wide range of advanced material handling solutions that are designed to optimize your operations, ensuring safety, efficiency, and ease of use. Below are detailed descriptions of the different types of material handling equipment we provide:

Key Highlights

Efficiency and Productivity: Our equipment is designed to streamline material transport and storage, significantly improving operational efficiency and throughput.

Customization: We offer highly customizable solutions, ensuring our equipment meets the specific needs of your industry and integrates seamlessly into your existing systems.

Durability and Reliability: Built with robust materials, our equipment is engineered for long-term durability and reliability, even in the harshest industrial environments.

Safety-First Design: Each product is designed with safety in mind, featuring advanced safety mechanisms and ergonomically friendly features to ensure the well-being of your workforce.

Versatility: Whether you're handling bulk materials, moving heavy loads, or stacking products, our range of equipment—including conveyors, stackers, and scissor tables—covers a wide range of applications.

Energy Efficiency: Our equipment is equipped with energy-efficient motors and systems, reducing operational costs and minimizing environmental impact.

Ease of Use and Maintenance: Simple, intuitive controls and easy-to-maintain designs make our equipment user-friendly, reducing downtime and increasing productivity.

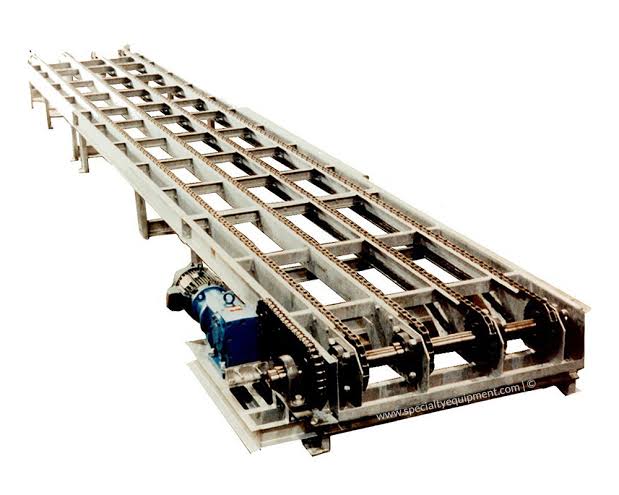

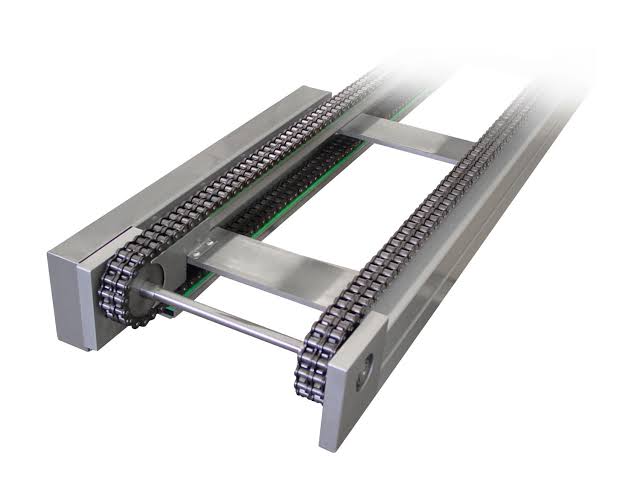

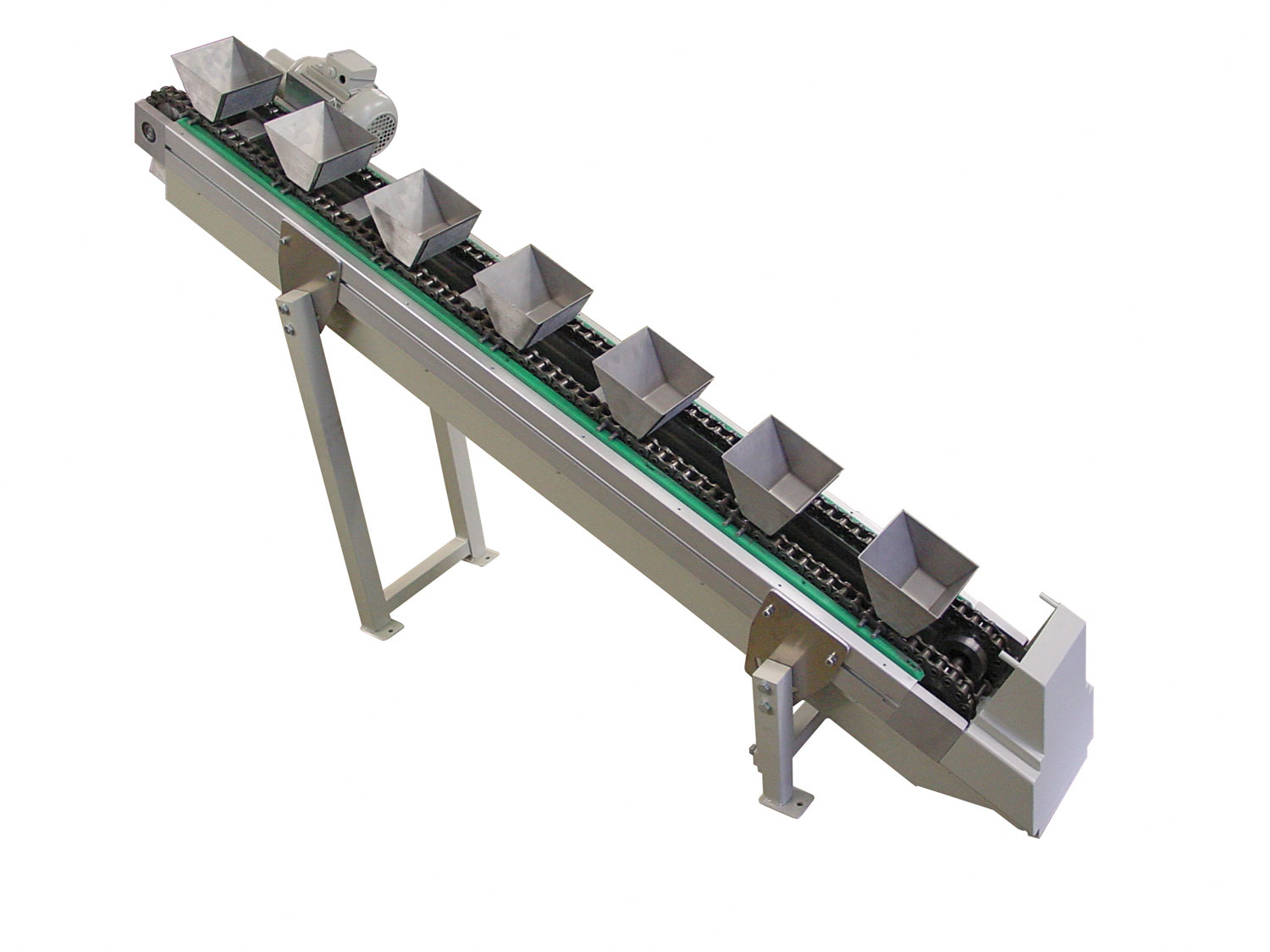

Conveyors

Conveyors are essential for moving materials, products, or packages through various stages of production and distribution. Our conveyor systems, including belt conveyors, roller conveyors, motorized roller conveyors, chain conveyors, and bucket conveyors, are designed for different applications. Conveyors offer consistent movement of bulk or packaged goods, helping to improve productivity and reduce labor costs. These systems can be customized for a wide variety of materials, with features such as adjustable speeds, modular construction for scalability, and safety mechanisms like emergency stops.

Features and Benefits

Versatile Applications: Our conveyors are ideal for a wide range of industries including manufacturing, food processing, logistics, and warehousing, offering flexibility in handling various materials.

Durable and Reliable: Built with high-quality materials, our conveyors are designed to withstand heavy loads and harsh conditions, ensuring long-lasting performance and minimal maintenance.

Energy-Efficient: With energy-efficient motors and systems, our conveyors help reduce operational costs while maintaining smooth and consistent material transport.

Modular Design: Our conveyors feature modular construction, allowing for easy customization and scalability to meet specific operational needs and space constraints.

Safety Features: Equipped with safety guards, emergency stop mechanisms, and anti-slip surfaces, our conveyors prioritize workplace safety and minimize potential hazards.

Smooth and Consistent Operation: Designed for smooth material flow, whether moving bulk goods or packaged items, ensuring minimal disruption to production processes.

Stackers

Stackers are essential material handling equipment used for lifting, stacking, and transporting materials, particularly in settings with high storage needs such as warehouses, factories, and shipping yards. These machines are specifically designed to enhance productivity by efficiently moving materials to elevated storage areas, thus optimizing space usage and facilitating easy access to goods. Stackers come in different types, including manual, electric, and hydraulic models, offering versatile solutions for varying operational requirements

Highlights of Stackers

Space Optimization: Stackers enable efficient use of vertical space, allowing materials to be stacked at higher levels, increasing storage capacity within limited floor space.

Versatility: Available in manual, electric, and hydraulic models, stackers can be customized to suit different types of materials, load capacities, and operational environments.

Improved Safety: With features such as stability locks, emergency stop buttons, and safety guards, stackers enhance workplace safety by minimizing the risk of accidents during operation.

Easy Maneuverability: The compact design and maneuverability of stackers make them ideal for use in tight aisles and crowded warehouse environments, ensuring efficient operations in confined spaces.

Increased Productivity: Stackers reduce the time spent manually lifting and stacking materials, thus increasing operational efficiency and speeding up workflows.

Features

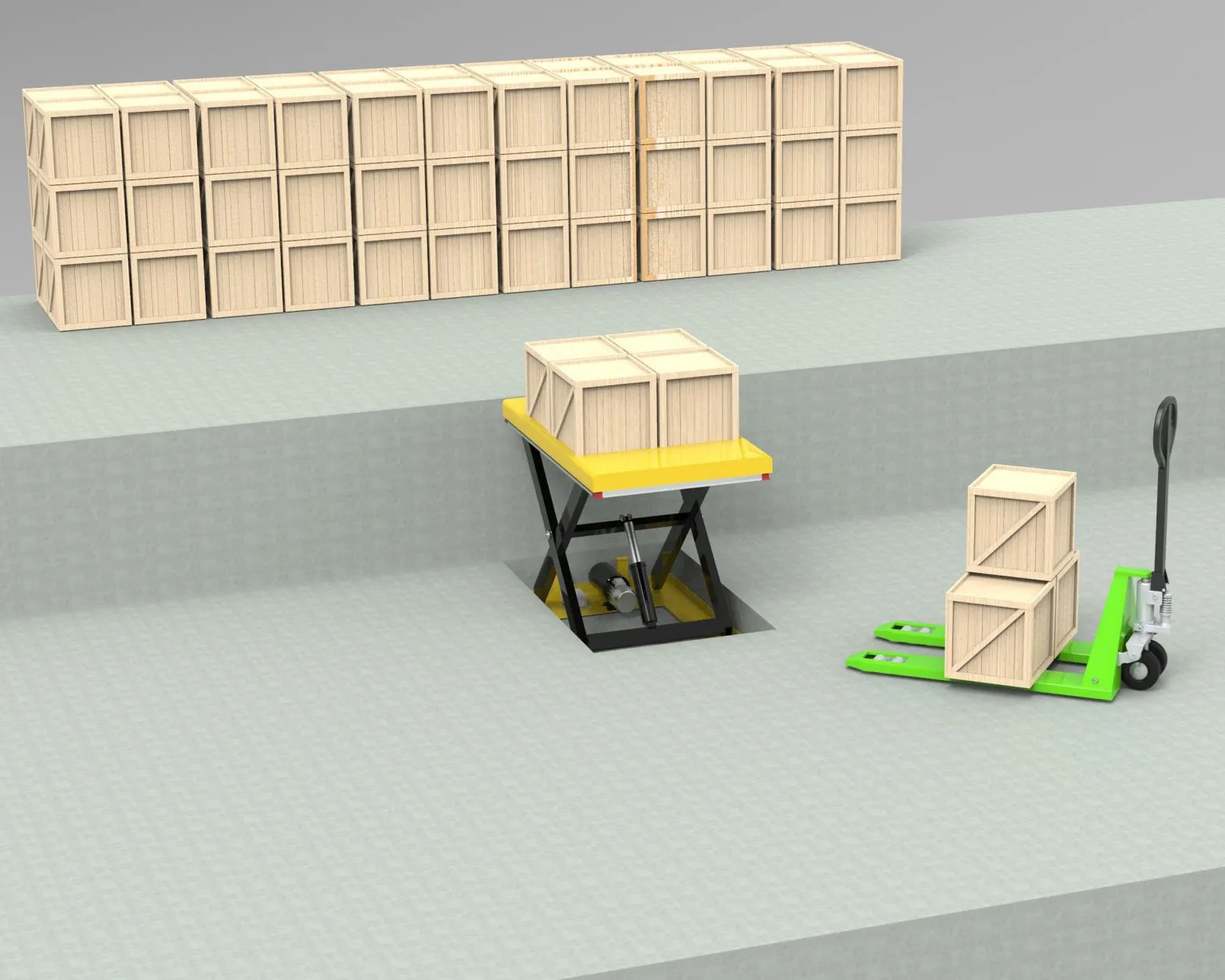

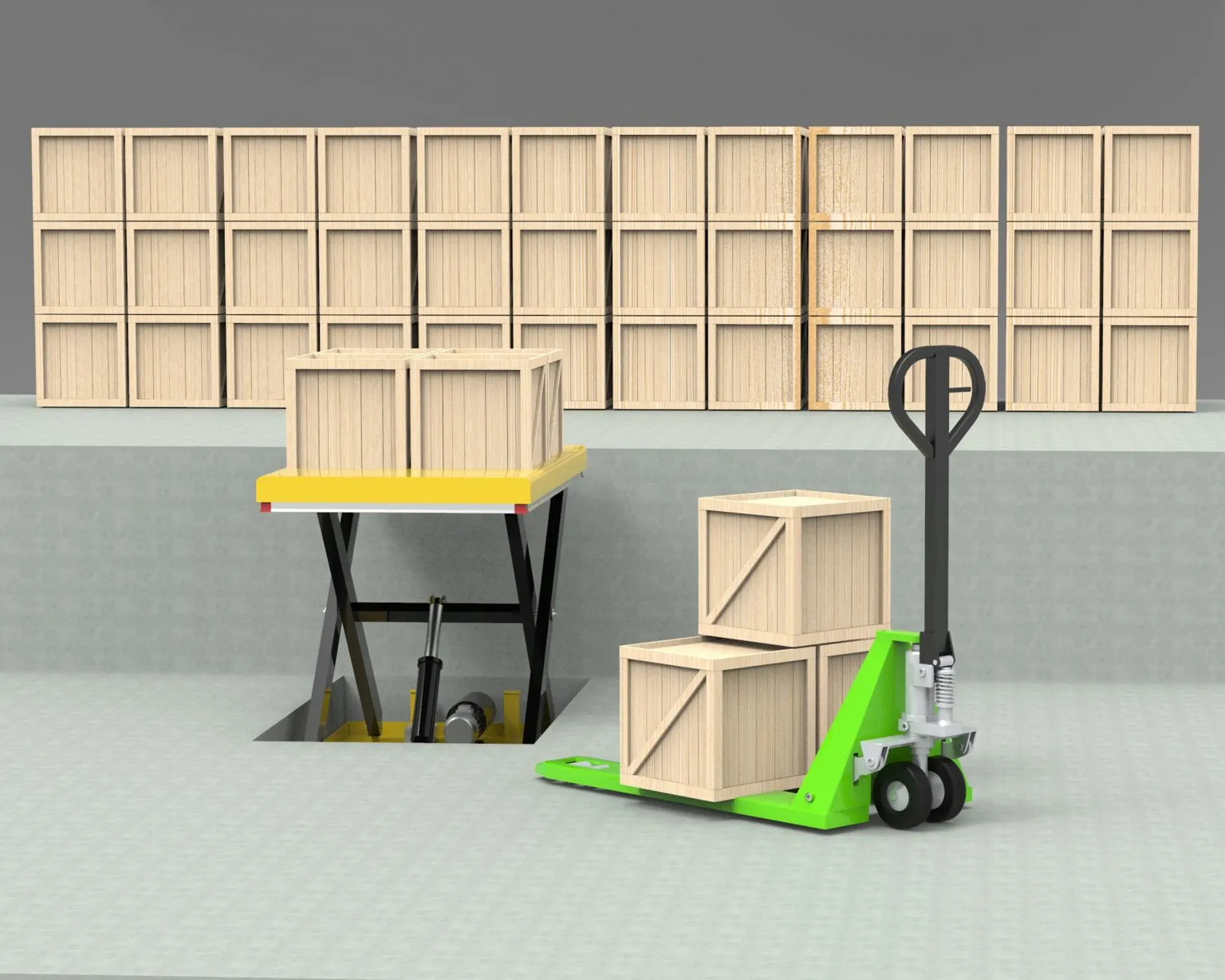

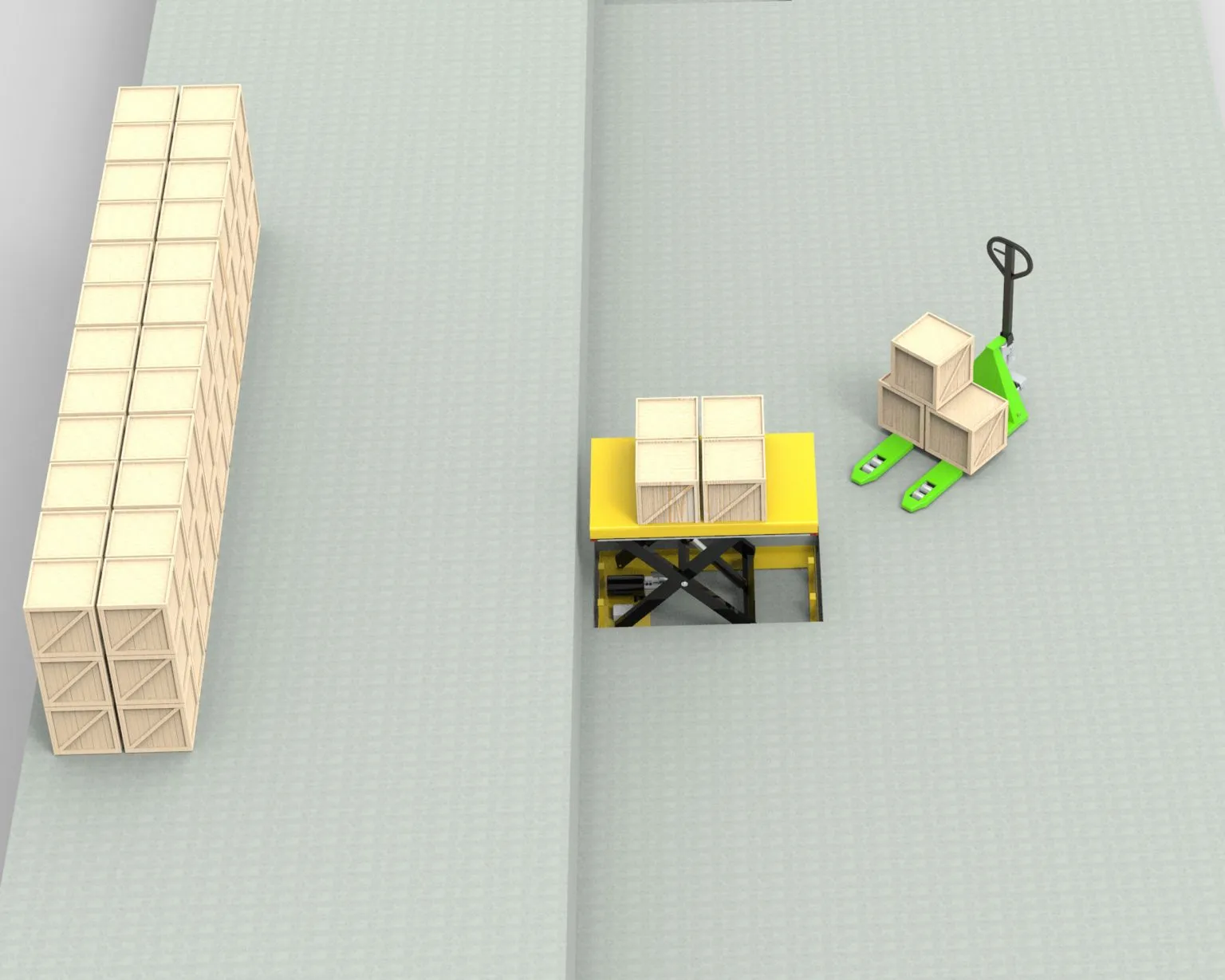

Manual/Electric/hydraulic scissor table

Manual/Electric/Hydraulic Scissor Tables are essential material handling equipment designed to raise or lower heavy loads to the required working height, ensuring more efficient and ergonomic loading, unloading, or assembly processes. These tables provide a convenient and effective solution for adjusting the height of materials, reducing the need for manual lifting and enhancing productivity. Scissor tables come in different variants—manual, electric, and hydraulic—each catering to different lifting capacities and operational needs.

Manual Scissor Tables: These are operated by hand using a foot pedal, lever, or manual crank. They are typically used for lighter-duty applications where occasional adjustments in height are needed.

Electric Scissor Tables: Powered by an electric motor, these tables provide smooth and efficient lifting and lowering. They are ideal for applications where frequent vertical movement is required but with less heavy lifting compared to hydraulic models.

Hydraulic Scissor Tables: Hydraulic models utilize hydraulic pumps to lift and lower the table. They are capable of handling heavier loads and providing precise control over vertical movements. These tables are designed for heavy-duty industrial applications where high lifting capacity is needed.

Key Features of Scissor Tables

Manual Models: Simple operation with hand or foot pedals for lifting and lowering. They are best for lighter-duty applications that require occasional height adjustment.

Electric Models: Equipped with an electric motor, these tables provide powered lifting and lowering, ideal for use in high-volume environments where quick and repetitive tasks are common. The electric models can be adjusted easily with the push of a button.

Hydraulic Models: Hydraulic scissor tables provide high lifting capacity, ensuring smooth and controlled vertical movements. They are perfect for heavy-duty tasks, such as lifting large industrial parts or machinery, and offer a stable platform for transportation or assembly.

Adjustable Height Range: Scissor tables typically offer adjustable height settings, making it easier to customize the working height to the specific requirements of the task.

Load Capacity: The load capacity of scissor tables varies based on the model. Manual models are designed for light loads, while electric and hydraulic models can handle heavier loads with ease.

Safety Features: Scissor tables often come equipped with safety features like anti-slip surfaces, emergency stop buttons, and locking mechanisms to prevent accidents during operation.

Benefits of Using Scissor Tables

Enhanced Productivity: By reducing the need for manual lifting, scissor tables help improve workflow and speed up operations, resulting in higher productivity.

Minimized Injury Risk: The ergonomic design and controlled movement of scissor tables reduce the strain on workers' backs, arms, and legs, minimizing the risk of injury.

Flexible Use: Whether lifting light, medium, or heavy loads, scissor tables can be configured to meet the specific needs of your workspace, offering a versatile and reliable solution.

What is material handling equipment?

Material handling equipment refers to machines or devices used to move, store, and manage materials in industries. It's essential for improving productivity, reducing manual labor, and enhancing safety.

How do I choose the right equipment?

Select material handling equipment based on factors like material type, weight, workspace layout, and required speed. Assess your operational needs and consult experts for the best solution.

What maintenance is needed?

Regular maintenance includes checking for wear and tear, lubricating moving parts, and inspecting safety features. Routine upkeep helps prevent downtime and ensures safe, efficient operation.